Noise Abatement

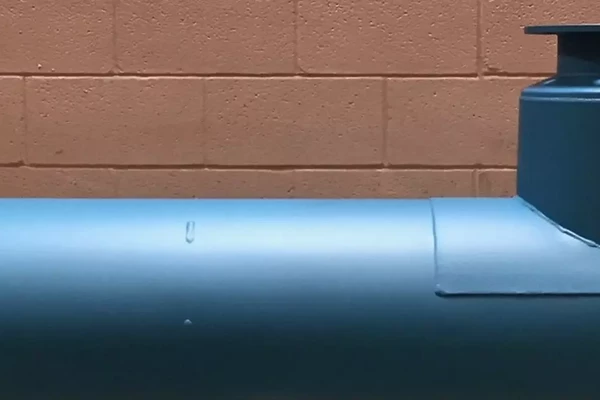

Dürr Universal designs and manufactures standard and custom industrial silencers for noise control, as well as air filtration solutions, to meet the most challenging application requirements.

Noise abatement solutions at a glance

Dürr Universal sound attenuation system design and development is supported by in-house acoustic, emission and dynamic testing laboratories. In-house technical centers, coupled with the company’s more than 65 years of design and manufacturing experience, enable Dürr Universal to engineer efficient and effective solutions for all applications from the most basic to the most complex.

Noise control solutions include:

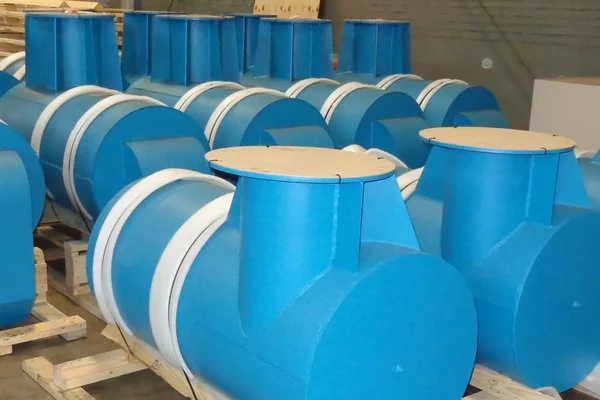

- Absorptive silencers

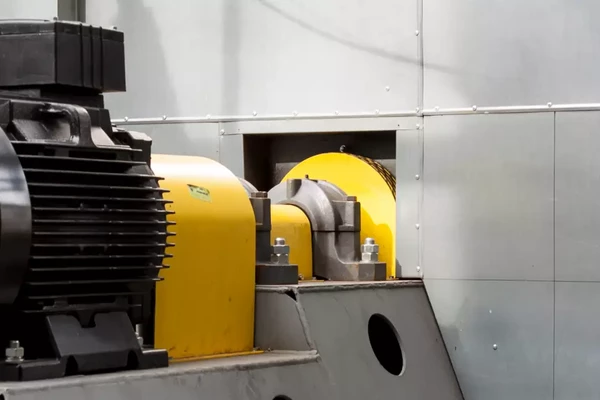

- Blower silencers

- Engine exhaust silencers and systems

- Vacuum pump silencers

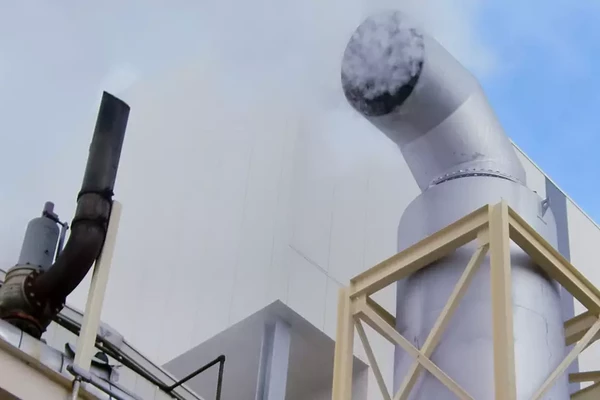

- Vent silencers

- Fan silencers

- Gas turbine noise abatement

These solutions are applied to a variety of process, pneumatic and power applications ̶ including rotary positive blowers, compressors, high-pressure vents/blowdowns, reciprocating engines, industrial fans and steam injectors.

Questions? Contact Us

WI Stoughton

United States

LE10 1YE Leicestershire

United Kingdom